Industry-pioneering automotive additive manufacturing opens the door to scalable tooling solutions, reduced lead times, and enhanced durability

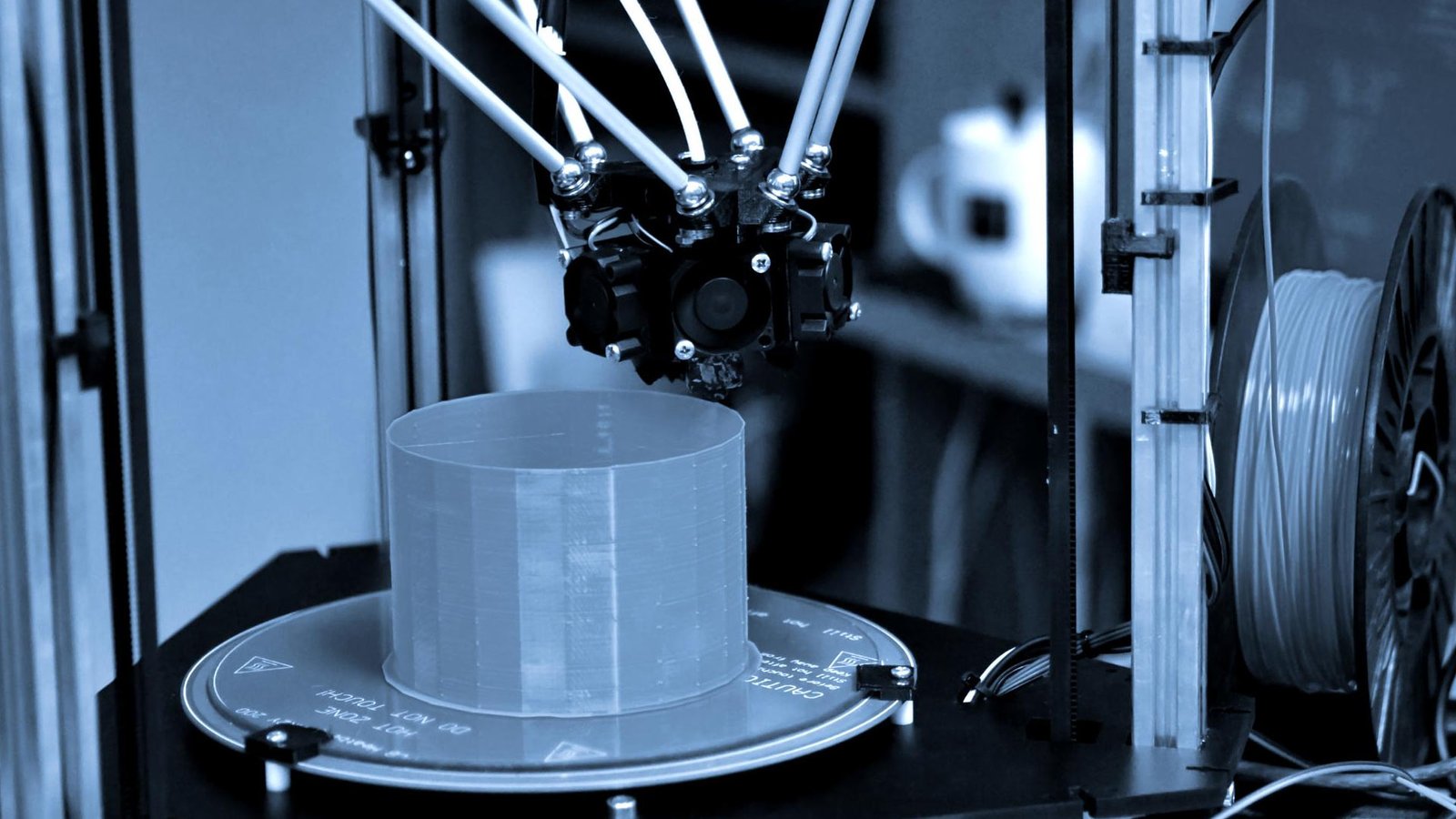

MacLean-Fogg Company (MFC) and Fraunhofer Institute for Laser Technology ILT (Fraunhofer ILT) have reached a new milestone in additive manufacturing for the automotive industry: creating the largest 3D-printed nearly solid die casting tooling insert in the world, 156 kg (350 lbs), for Toyota Europe’s Yaris hybrid transmission housing.

Record-Breaking Scale in Automotive Tooling

A conformally cooled insert, allegedly the largest in the world, was produced using Fraunhofer ILT’s gantry-type, multi-laser Laser Powder Bed Fusion (LPBF) machine with MacLean-Fogg’s patented L-40 tool steel powder. A hybrid process was utilized in consideration of Toyota’s cost targets.

OEM Validation from Toyota Europe

“Gantry printing with L-40 tool steel powder material, a promising avenue towards scalable additive manufacturing, is opening the potential for metal 3D printing to reduce lead times and to realize more responsive manufacturing— in particular while delivering world-class insert performance, longer maintenance intervals, and cost-effective pricing structure,” said Dr. Magdalena Coventry and Dr. Andrew Willett, Toyota Europe. “We are thrilled to be at the forefront of innovations in the rapidly developing universe of additive manufacturing.”

Advanced Materials for Automotive Manufacturing

MacLean-Fogg’s L-40 powder was specifically designed for the LPBF process to achieve high hardness and toughness, thereby minimizing crack formation and crack propagation even when printing at moderate pre-heat temperatures. Compared to conventional tool steels, L-40 also reduces the need for advanced post-build heat treatments, further decreasing time-to-market. Additional benefits include:

- Reduced the soldering of aluminum to the tooling surface

- Approximately twice the lifespan of conventional aluminum die-casting inserts

- Lower overall tooling maintenance requirements

- High sustainability, with no cobalt and a minimal amount of nickel

“Toyota posed a thrilling challenge by requesting to expand the application of L-40 to large-format tooling inserts,” said MacLean-Fogg’s Director of Product Development, Dr. Harald Lemke. “We had to overcome scale-up challenges such as ensuring consistent gas flow conditions as build sizes grew.”

Next-Generation 3D Printer Platforms

Fraunhofer ILT addressed these requirements with its gantry-type, five-laser LPBF system, which allows for the processing of parts longer than 50 cm in side length and chamber temperatures of up to 200°C.

“This was precisely our motivating factor to develop the gantry system,” said Dr. Niklas Prätzsch of Fraunhofer ILT. “L-40’s unique attributes make it possible to perform large-scale additive manufacturing of tooling inserts at lower temperatures without compromising quality.”

Unlocking the Future of Automotive Die Casting

By demonstrating this success, Fraunhofer ILT and MacLean-Fogg aim to expand the technology into structural die casting, inserts for giga-casting tools, and other large hot- or cold-forming tools where traditional powders have not yet been validated. All these are consistent with broader trends in the automotive industry towards lightweighting, shorter development times, and local supply chain resilience.

See the Innovation in Person

- NADCA Die Casting Congress & Exhibition – Dr. Harald Lemke to present on October 7 in Milwaukee, USA.

- Formnext 2025 – MacLean-Fogg to showcase this innovation November 18–21 in Frankfurt, Germany. Halle 11.0 A58

Discover the latest trends and insights—explore the Business Insights Journal for up-to-date strategies and industry breakthroughs!