Automation is transforming factory floors. Find out how your operations can evolve to compete in 2025.

Material handling and assembly used to be about throughput. Today, it’s about adaptability. As global supply chains stretch thin and customer expectations accelerate, businesses no longer ask if they should invest in automation—but how fast they can do it. Automation in material handling and assembly is no longer a back-office engineering concern. It’s a C-suite mandate tied directly to resilience, productivity, and long-term competitiveness.

Manufacturers now face a pivotal decision: modernize legacy systems or risk operational stagnation. And it’s not just about robots on the floor—it’s about intelligent orchestration across every movement, decision, and delay in the line.

Table of Contents:

1. From Robotics to Cognition

2. Data Becomes the Conveyor Belt

3. Human-Machine Collaboration Gains Strategic Value

4. Logistics as a Competitive Differentiator

5. Moving Beyond ROI to Resilience

Final Take

1. From Robotics to Cognition

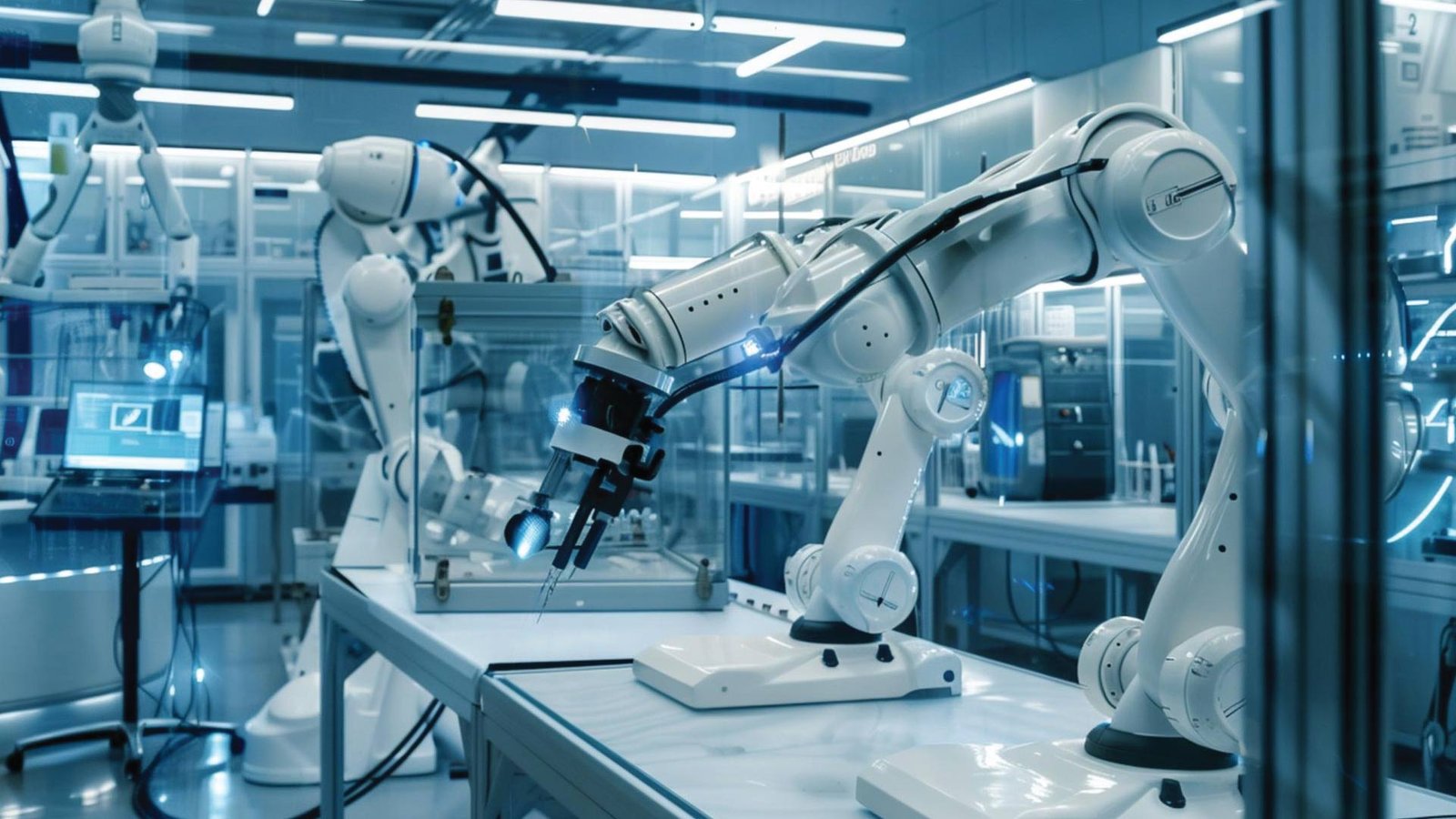

Robotic assembly lines have evolved from rigid, pre-programmed arms to intelligent, adaptive systems. In 2025, smart robots powered by AI and machine vision aren’t just following instructions—they’re making micro-decisions in real time.

Leading factories deploy automation technologies used in modern assembly lines that self-optimize based on load balancing, predictive maintenance data, and inventory flow. Tesla’s Giga factories, for instance, leverage cognitive automation for everything from battery assembly to final inspections, reducing cycle times by 18%.

Yet many companies still treat robotics as a static investment. The real value lies in the intelligence layer—where data and decisioning converge.

2. Data Becomes the Conveyor Belt

In modern material handling and assembly, data is the new infrastructure. Digital twins, IoT sensors, and edge computing now dictate the speed and accuracy of every physical movement on the floor.

Advanced analytics platforms allow operations to simulate entire production scenarios, anticipate bottlenecks, and dynamically reroute materials. Leaders who understand this treat data pipelines as strategically as mechanical ones.

3. Human-Machine Collaboration Gains Strategic Value

Factory automation technology isn’t replacing humans—it’s redefining their role. Cobots (collaborative robots) are now embedded across major production environments, working side-by-side with technicians to improve safety, precision, and efficiency.

According to a 2025 Deloitte report, 78% of manufacturing executives believe hybrid human-robot teams outperform fully automated ones in complex assembly tasks. But making this work requires more than tech upgrades. It requires redesigning workflows and investing in cross-functional training.

The smartest automation strategies don’t eliminate people—they elevate them.

4. Logistics as a Competitive Differentiator

Material flow is now a board-level concern. Autonomous mobile robots (AMRs), real-time tracking systems, and intelligent sortation units are helping factories transition from reactive fulfillment to proactive logistics. But one of the biggest challenges of automating material handling processes is integration—especially across legacy warehouse management systems (WMS) and enterprise platforms.

When logistics moves at machine speed, delays are no longer tolerated—they’re strategically addressed. Leaders who get this right gain a serious edge in time-to-market, flexibility, and cost predictability.

5. Moving Beyond ROI to Resilience

Traditional ROI metrics fall short in today’s volatile environment. The true impact of automation in material handling and assembly lies in its ability to deliver uptime, agility, and adaptability under pressure.

By 2025, resilience—not just efficiency—will be the leading benchmark for automation success. Businesses must shift their mindset from short-term cost savings to long-term operational continuity.

Final Take

Automation isn’t just changing how factories operate. It’s redefining what a competitive manufacturer looks like. The question C-suite leaders must ask is clear: are you automating for tactical improvement or for strategic transformation?

The factories that win won’t be the ones with the most robots. They’ll be the ones that built intelligence, flexibility, and foresight into every layer of their material handling and assembly operations.

Discover the latest trends and insights—explore the Business Insights Journal for up-to-date strategies and industry breakthroughs!