SKF announces a strategic partnership with Sieb & Meyer, a renowned expert in variable frequency drives (VFDs) and control electronics. The collaboration marks a significant milestone in delivering integrated, high-efficiency inverter solutions tailored for demanding applications such as air compressors, turbo-blowers and HVAC (Heating, Ventilation, Air Conditioning) systems.

Under the partnership, SKF will manufacture variable frequency drives at its facilities, leveraging Sieb & Meyer’s advanced design expertise and decades of experience in high-speed drive technology. Customers will benefit from a seamless, plug-and-play solution that simplifies integration, reduces engineering time, and increases confidence in system performance, as well as offering long-term scalability into new applications.

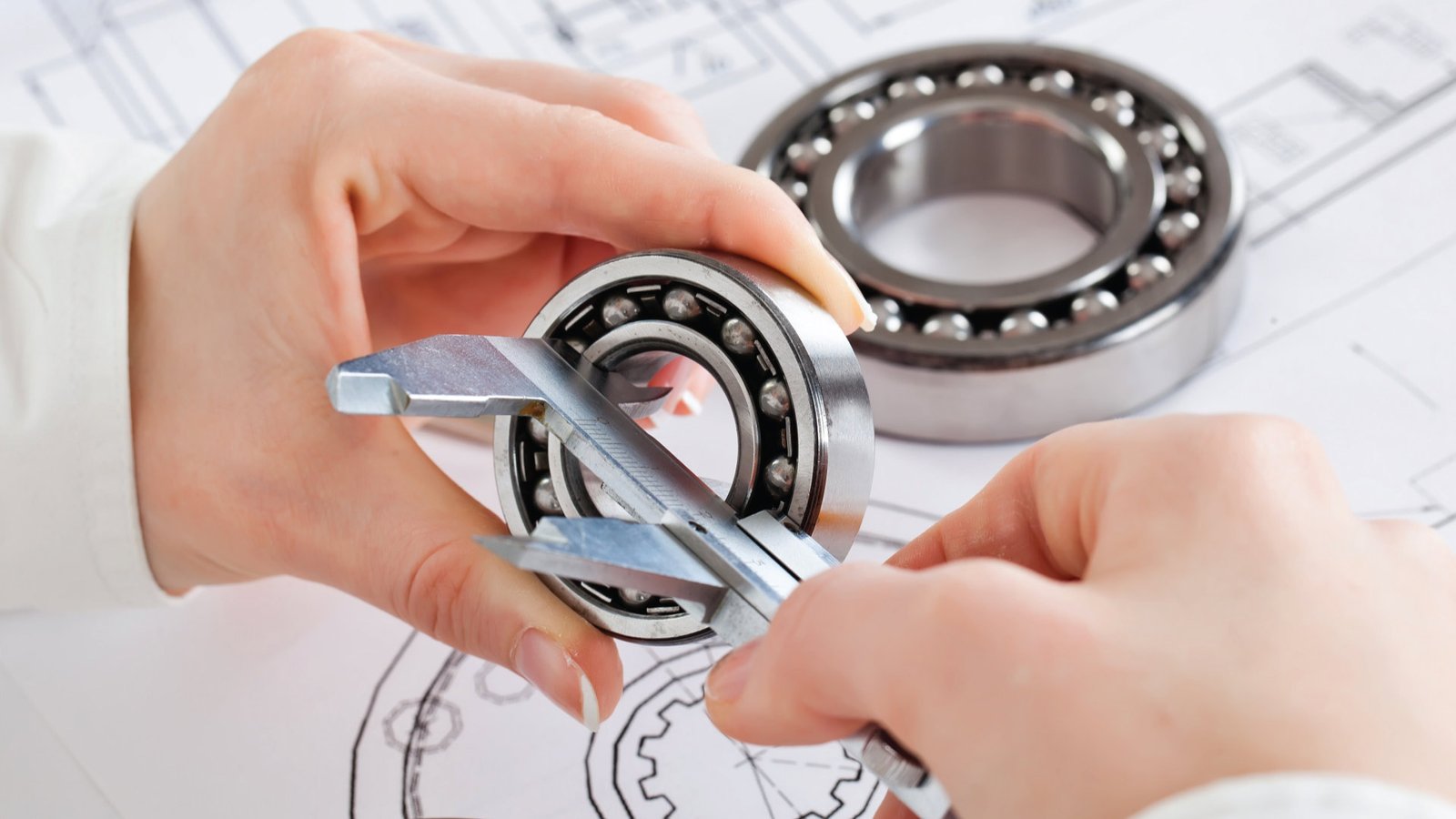

The collaboration will enhance SKF’s offering by delivering an optimized package, combining SKF’s high-speed electric motors on magnetic bearings with VFDs that are precisely tuned for performance, reliability, and energy efficiency.

“By combining our magnetic mechatronics capabilities with Sieb & Meyer’s VFD technology, we’re creating a new standard for high-speed motor systems. This partnership allows us to offer a more complete and efficient solution to our customers,” says Frederic Ponson, Director of SKF Magnetic Mechatronics.

“This partnership represents a powerful alignment of expertise. By integrating Sieb & Meyer’s advanced inverter technology into SKF’s high-speed motor systems, we’re delivering a smarter, more efficient solution that meets the evolving demands of HVAC, air compressor, and blower applications. Together, we’re setting a new benchmark for performance and reliability,” says Markus Meyer, CEO at Sieb & Meyer.

Moving forward, the partnership will expand its scope to include boil-off gas compressors and spindle drive systems, further broadening the range of industries that can benefit from this integrated approach.

In general, sustainability benefits from SKF’s magnetic bearing systems include a reduction in energy use and the elimination of oil-related pollution in comparison with conventional solutions using rolling bearings. In energy-intensive applications like wastewater treatment, compressed air, or HVAC, high speed electrical motors levitated on magnetic bearings machines can cut energy consumption by up to 30%, translating to 10–15% savings for entire facilities, lowering greenhouse gas emissions from electricity generation.

Discover the latest trends and insights—explore the Business Insights Journal for up-to-date strategies and industry breakthroughs!